The beating heart of innovation

Li-Con is spread over 600 square meters and consists of 2 departments: the engineering department and the prototypes and test laboratory.

The engineering departments design following customer input and the prototypes are realized and tested by the laboratory department.

Concept development

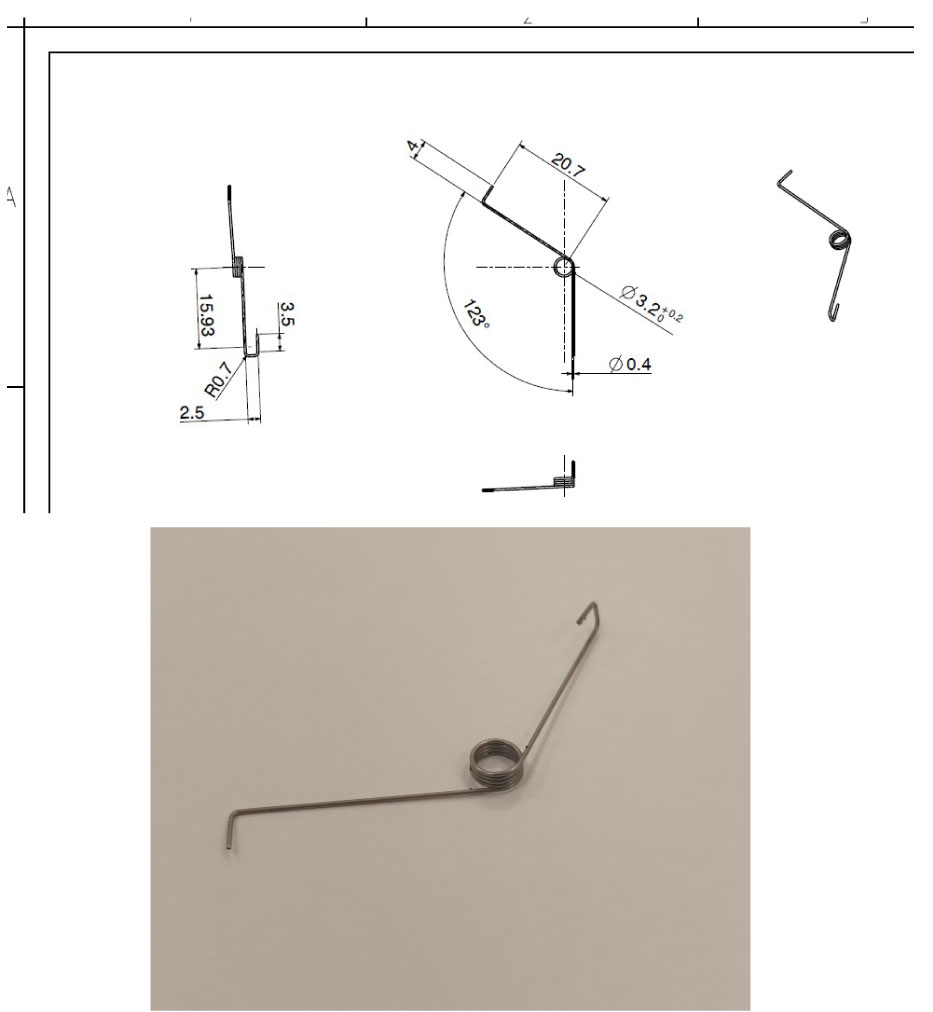

Starting from what customer needs, Li-Con develops a “proof of concept” (cad or a prototype).

It is the beginning of the product development process.

Design and analysis

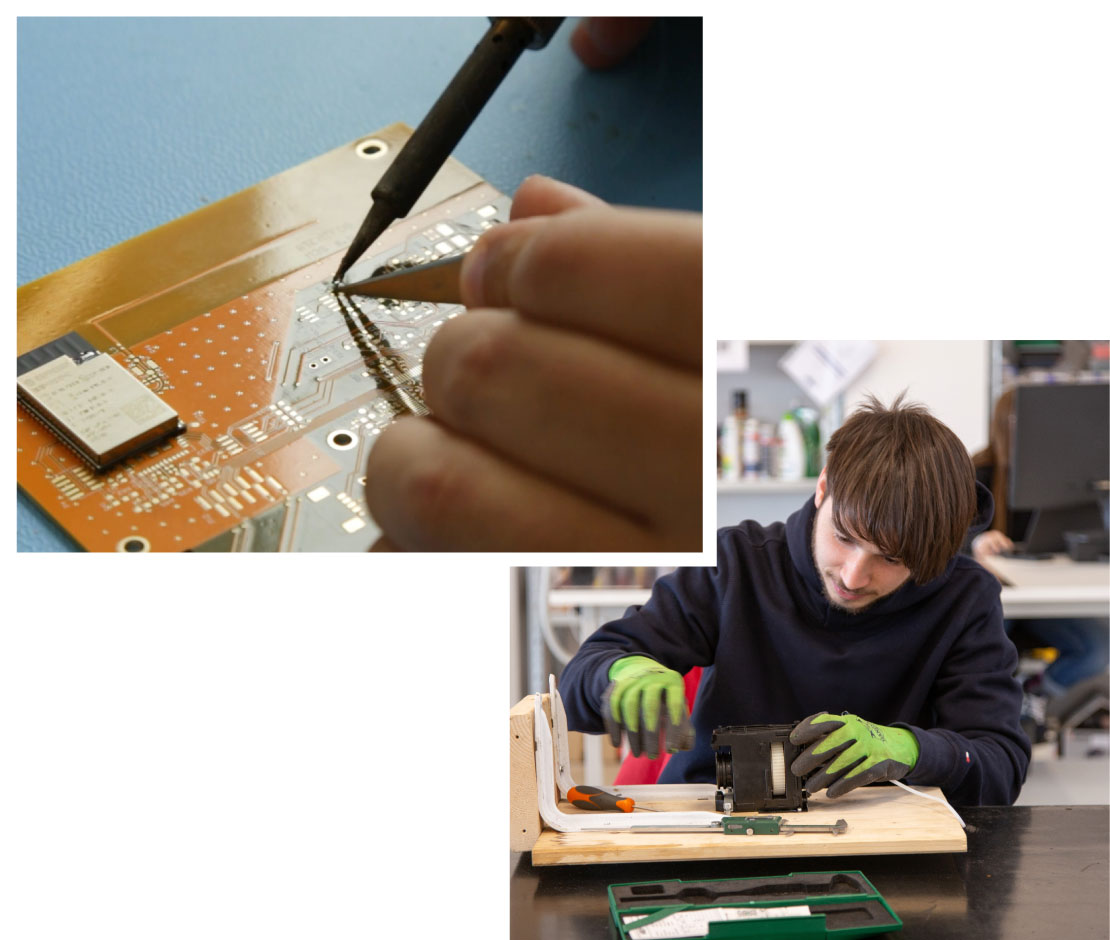

Customer’s product ideas are developed by the Li-Con engineering department, covering both the mechanical and electronic field. The cooperation of a team of mechanics and electronics guarantees the optimal result of the designing process.

Prototypes making and testing

Customer’s ideas “come to life” thanks to the Li-Con laboratory: what has been designed on CAD is prototyped and tested.

Validating prototypes in the early stage allows to anticipate any problems that would be hardly solved after the start of production.

Problem solving

Li-Con works thoroughly to identify the causes of a product malfunction or shortcoming; then, Li-Con provides the solutions to eliminate them . Quoting Einstein said: “If we had an hour to solve a problem, we would spend 55 minutes thinking about the problem and 5 minutes thinking about solutions”.

Industrialization

Li-Con supports customer in the industrialization phase, which consists in identifying the best design, materials and processes to make the components and assemble them in the final product.

Li-Con provides the necessary documentation and support in the assembly line, necessary for the production.

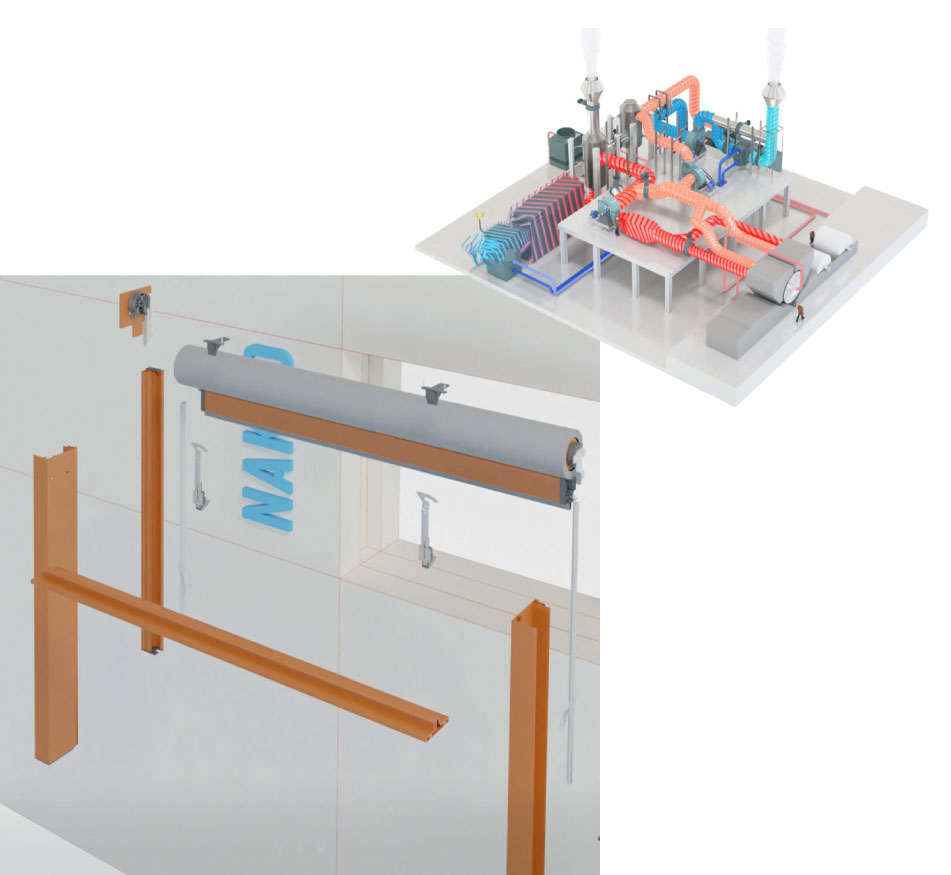

Rendering and 3D animation

3skel is a Li-Con partner. It creates graphics and 3D animations of products. These allows the customer to have insightful previews of the final product that can be showed to any stakeholder.

Get more information on 3skel.